July 11, 2023

Should You Repair or Replace Your Road Case?

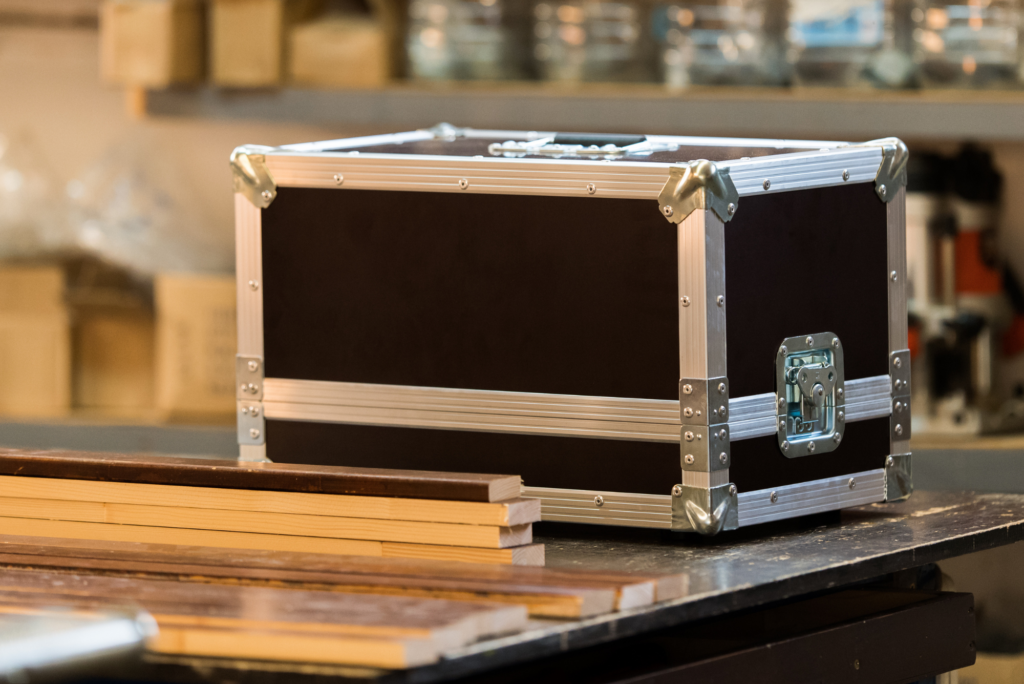

A high-quality road case can be a big investment, so you’ll want to get as much use out of it as you can.

But accidents happen — especially on the road — and sometimes you end up with damage duct tape can’t fix. Does that mean you have to retire your road case early?

Not necessarily. Expert carpenters can repair even severe road case damage. But that leaves one question: is repair work worth it?

Repair 101: The Most Common Types of Road Case Damage

At Kangaroo Cases, we’ve seen it all. Here’s everything you need to know about the most common types of road case repairs we perform.

1. Broken or Worn-Out Latches

Latches see a lot of use, and they wear down over time. They’re also easy to outright break. For example, leaving a latch open puts it at risk of being knocked off the case.

Repairing latches is a quick and straightforward process. We remove the damaged latch hardware and rivets, then replace them with new ones that closely match the original. The end product is a case that’s good as new.

2. Caster/Caster Board Damage

Ever had a “crazy” wheel on your shopping cart? That issue intensifies when you need to maneuver hundreds of pounds of sensitive equipment up ramps and through tight walkways.

A broken caster wheel makes transportation strenuous and potentially dangerous, which is why these kinds of repairs are so common. But caster repair is as easy as latch repair — it’s a simple, high-quality parts replacement.

If the caster board is also damaged, however, the repair requires more work. We cut a new caster board out of ¾″ plywood, then attach it with T-nuts fed through the case. This kind of repair results in a sturdier build than other cases.

3. Panel Damage

High-quality road cases can handle a lot of abuse, but even the toughest cases are no match for a forklift. Sometimes, in the bustle of transportation, the fork goes straight through a case panel like a hot knife through butter.

To address this and similar disasters, we deconstruct the broken panel and cut a new one to match. After we install the new panel, we reattach the hardware and any metal fixtures. Then the case is ready to use again.

4. Foam Damage

After years and even decades of use, foam inserts tear, become loose, or simply wear down. Foam deterioration puts equipment at greater risk of damage from shocks and bumps, so even if it doesn’t seem serious, repair is important.

We can easily reattach loose foam. A repair like this can appear simple enough to DIY, but we don’t recommend using common glues. Professionals have the right materials and equipment to perform a long-lasting repair.

We don’t see ripped foam often, but when we do, we replace it. We ensure your equipment is as safe as possible by cutting new foam to your case’s exact measurements.

5. Other Types of Damage

We’ve seen it all — an emergency repair for a touring band, a footlocker wheel replacement, a lid with a damaged tongue and groove, etc. Whatever the damage, we can repair it.

Kangaroo Cases’ Repair Policy

We can repair any case, no matter the original builder. In fact, about 99% of the cases we repair are from other manufacturers!

While we may not be able to match every material one-to-one, we do our best to make each case look brand new and ensure it protects like a mother.

Every repair is different, so our pricing varies by case. We’ll provide a quote after you drop off your case, or after you send sufficient photos of the damage.

Repair or Replace: What Should You Do?

Whether you choose to repair or replace your case is ultimately a question of value.

In some instances, it’s more expensive to repair a case than it is to replace it. Keep in mind that you’ll need to cover not only the costs of the repairs and any demos, but shipping both ways.

Kangaroo Cases can help with both repairs and replacements. Contact us today to get the ball rolling.