September 19, 2023

Truck Packs 101: How to Pack Your Cases Like a Pro

Is your truck-packing strategy slowing you down? Complicated packs, wasted space, and other common issues can cost you hours on the road.

One way to improve your fleet’s efficiency is to use truck cases. Truck cases bring uniformity to your fleet and help you maximize your trailer space.

What Are Truck Cases?

Truck cases are road cases built to exact, standardized sizes that are generally perfect fractions of a truck’s 90-inch width. With truck cases, you can stack and load road cases like Tetris blocks, completely filling the available space without waste.

The largest truck packs are 45-inch-wide half packs. Two of these side by side will exactly fill a 90-inch truck. Then there are third packs at 30 inches, and quarter packs at 22.5 inches, which can be lined up three across and four across, respectively.

Some cases can be configured differently. For example, while quarter packs are 22.5 inches in depth, they’re usually the same width as half packs. This makes it easy to mix and match rows. So, if you only need three quarter packs, you can turn one into a half pack to fill the row and save space.

Pros and Cons of Using Truck Cases

Are truck cases right for you and your needs? Weigh the pros and cons to make your decision.

Pros of Using Truck Cases

Consistent sizing across your fleet is the main benefit of using truck cases. Reducing the number of custom-sized cases makes packing more efficient by eliminating wasted truck space and simplifying your packing strategy.

Truck cases can also speed up load-in and load-out times. They may even be easier to maneuver on site.

10 Tips for Choosing

the Perfect

Custom ATA Road Case

Learn how to protect your valuable gear with custom-built road cases designed specifically for your equipment.

Cons of Using Truck Cases

Truck cases aren’t a flawless solution.

Your assets probably weren’t designed with standard-sized truck cases in mind, meaning you’re unlikely to get a perfect fit. This could result in less-than-adequate protection for your equipment. For example, you may have to use less foam to fit a large asset in a small case.

In addition, the more you fit into a trailer, the heavier it will be. It’s easy to overpack a truck from a weight standpoint if you use truck cases. Also, matching cases can make it harder to identify your assets once they’re packed.

How to Optimize Truck Cases

Truck cases are already easy to use, but you can take this a step further by optimizing how you use them. The two most important factors to optimize are weight and strategy.

Optimizing Truck Case Weight

Depending on the size of your cargo, the most efficient packing can result in an overweight trailer. You need to know not only how the cases fit together, but also how heavy they are.

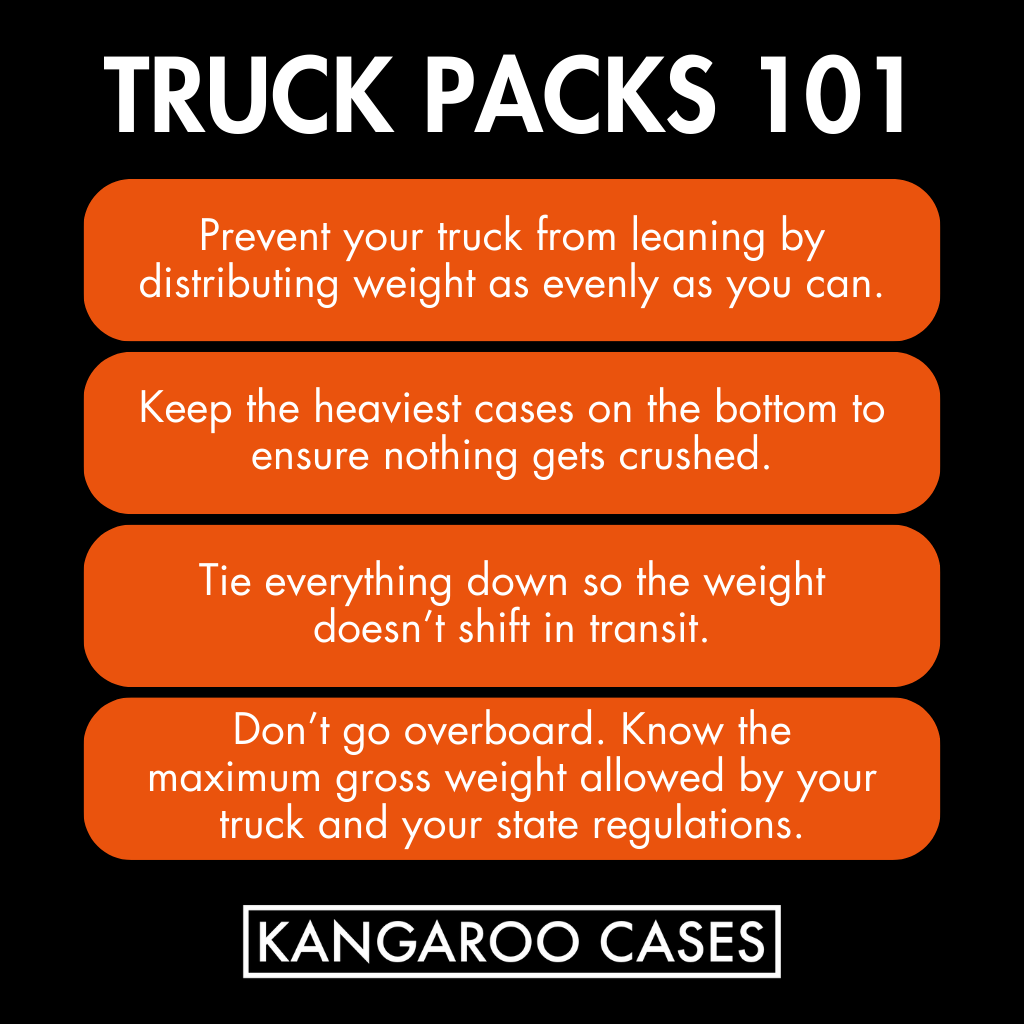

Here are a few things to keep in mind when you pack your truck:

- Prevent your truck from leaning by distributing weight as evenly as you can.

- Keep the heaviest cases on the bottom to ensure nothing gets crushed.

- Tie everything down so the weight doesn’t shift in transit.

- Don’t go overboard. Know the maximum gross weight allowed by your truck and your state regulations.

Optimizing Truck Case Strategy

A road case strategy is the plan of action for all your cases — from their design to their role to how you move and store them.

When it comes to truck cases, the best packing strategy is to load each row from floor to ceiling. You should be looking at a full wall of cases before moving on to the next row. This makes stacking easier, prevents awkward stooping, and expedites the load-in and load-out process.

Once you’ve perfected your strategy, don’t forget to document it. Write down your processes step-by-step and take pictures of your packs for future reference.

Build Your Fleet of Truck Cases Today

When you use them right, truck cases can make packing your equipment a breeze. No math, no fuss, no complicated instructions for your team members.

Ready to build your fleet? Kangaroo Cases has standard truck cases in half-pack, third-pack, and quarter-pack sizes. Check out our product page for more information.